Region of Coquimbo | Chile

-

2023-2024

Project date

-

Savings of

80.23tin CO2 emissions

-

Savings of

35tof steel in prototypes

A benchmark in energy and sustainability, Ferrovial Construction’s Lead Technical Team has been working on numerous research projects on the behavior and optimization of electrical transmission towers in recent years.

Specifically, the Centella power line project in central-western Chile led the team to develop a new methodology to structurally validate the towers, in order to minimize the cost of full-scale testing and generate confidence and trust in the towers installed.

This new methodology was developed, tested, and documented in parallel with the project’s conventional static tests. This aimed to determine the validity of the methodology, obtain an objective view of savings, and enable the system to be implemented on any power transmission line in any geographical location.

Structural validation of high-voltage towers through dynamic testing and advanced virtual modeling

The methodology enabled the validation of installed towers through simple dynamic testing, correlating responses with the results previously obtained through virtual modelling. In Chile and other countries to date, the usual practice consists of performing static tests on tower testing stations, installing full-scale towers and stress-testing cables until failure point.

All of these actions, procedures and conclusions—both for the generation of virtual models and field operations—have been recorded, representing a body of methodology data for implementation on future power line infrastructure projects, both for new constructions (the goal of this particular innovation) and the structural validation of existing power lines.

Summary of works

A working group is set up with internal personnel from Ferrovial Technical Directorate’s Civil Works Department to address the project’s technological objectives following the conceptual design of the method. Centella is charged with significant works on research and validations, while external collaborators specializing in dynamic calculations and sensorics join the project: the Mechanical Structures Group at the University of Coruña and Metri Consulting, respectively.

The tasks are subdivided into the following milestones:

- Developing advanced virtual models.

- Designing and executing the testing plan.

- Calibrating computational models, obtaining correlation parameters, and validating results.

- Developing the methodology for future replication.

Developing advanced virtual models

Initial works focus on the development of virtual models in SAP2000 and Abacus, which should be an image of the test plan towers for two reasons: to enable the validation of the same, drawing on data extracted from conventional testing, and generating correlation parameters for the new testing methodology.

This led to the incorporation of 3D-modelled joints and the analysis of various effects such as prestressed bolts, friction contact, non-linear materials, and geometric non-linearity, assessing the impact on the structure’s natural frequencies and vibration modes.

Designing and executing the testing plan

The testing plan was initially forecast to be performed entirely on the full-scale towers installed at the Romanian test station (Bucharest). However, given that the static testing coincided with COVID travel restrictions, the decision was taken to maintain the planned schedule and postpone dynamic testing, implementing tests on the actual towers installed in Chile, correlating both sets of results with the virtual models.

Throughout this process, desk work was performed on coordination and training as well as the analysis of models to assess the optimal placement for acceleration sensors, tower excitation methods and fault simulation at connections.

Lastly, dynamic tests were carried out on two of the towers, sequentially applying a single load at different points of the towers and examining the vibrations occurring in the structures under the impact of said load. These vibrations were collected via accelerometers located at 8 points of the tower (at different heights), with the acceleration data subsequently being collected by a receiver.

Calibration, correlation parameters, and the validation of results

Using data gathered via dynamic testing, the team proceeded to a final calibration of the models, also obtaining correlation and validation parameters. Overall vibration modes, damping, the influence of foundations on natural frequencies, and the influence of bolt slip were identified, along with an analysis of frequency alteration caused by faults in profiles or loose connections.

Developing the methodology for future replication

The results obtained in field tests, contrasted against numerical models, generated a final document outlining the conclusions and methodology of application, including recommendations and procedures for the future replication of these dynamic tests. The goal is to validate transmission towers in the field without the need to construct full-scale prototypes and test them to collapse or failure load.

To conclude, we successfully developed a new method of structurally validating transmission towers in their final locations, using low-load dynamic testing correlated with advanced virtual modelling. This new methodology represents a disruptive shift in industry practice.

To promote this significant industry shift, we have begun to disseminate the procedures and conclusions at various conferences and seminars, the first being the Seville Structural Dynamics Conference in September 2024.

Our Projects Around the World

Learn about them

407 ETR

New Terminal One, JFK International A…

LBJ Express

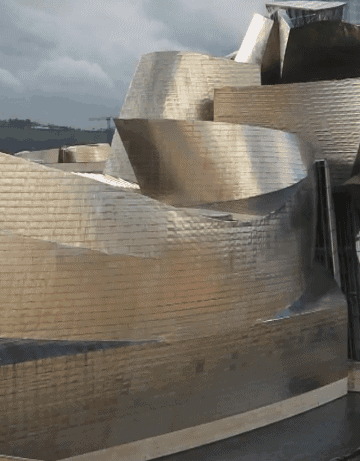

Guggenheim Museum

North Tarrant Express