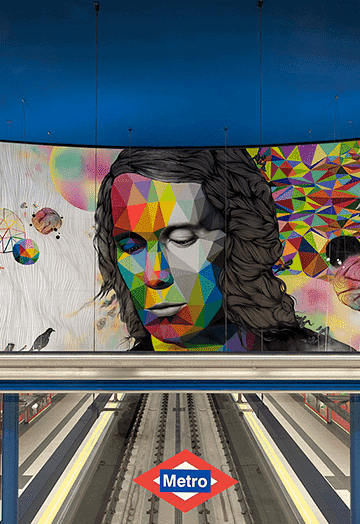

Seville (Spain)

-

Since

1968building the Portico

-

Professionals

41in the assembly

-

Parts

4.000connected

-

Tons

20Tof roof weight

Every spring, the Seville April Fair is inaugurated with the turning on of the façade lights. This structure, with a metal base and a design that changes annually, is the gateway to this emblematic celebration and a symbol of one of the most important weeks of the year for the Andalusian city. Ferrovial is one of the companies that contributes to making one of Spain’s best-known and best-loved festivals a reality.

In 1896, the engineer Dionisio Pérez Tobías designed a metallic structure that was installed at the intersection of the Real de la Feria and soon became a symbol as the entrance to the Seville Fair. Decades later, the structure was dismantled, but popular desire and what had by then become tradition led to the installation of temporary entrance gates in each subsequent edition of the fair.

From 1968 to the present day, these entrance gates have been built by Ferrovial Agroman and, subsequently, by Ferrovial Construcción. Today, the entrances measure some 45 meters high and 50 meters long and are made up of a complex network of more than 4,000 pieces of different materials.

Entrance gates over the years

2008

2009

2010

2011

2012

2013

2014

Throughout the shared history of the April Fair and Ferrovial, the entrance gates have taken on several different personalities. Every year, the City Council of Seville organizes a contest to choose the design for the following spring. This contest often has a specific theme and seeks to reflect the character of an emblematic building or recall a historical event. This has given rise to memorable gates such as that of 2010, which celebrated the centenary of the first flight over Seville, or that of 1993, inspired by the old Pedro Roldán warehouses in the city.

At other times, the theme is open. In these cases, the designs tend to maintain the spirit that always accompanies the fair: bright and cheerful colors to represent the flowers that bloom anew with the arrival of spring.

This is how the April’s Fair Portico is built today:

- The construction of the entrance gate starts in early December. Over the course of two months, a large three-dimensional tubular structure is erected, made up of metal parts assembled together. The key to this construction lies in the tube coupler, a part weighing just one kilogram and with a sliding resistance capacity of 1,000 kilograms. Thousands of linear meters of pipe, tens of thousands of bolts, and several tensioning cables are also involved.

- In early February, the roofs, which have a total weight of about 20 tons, are hoisted. Occasionally, this phase has added complications: in 2010, for example, the structure featured a replica of the Bleriot XI, the first aircraft to fly over Seville. The 3,500-kilogram structure hung from the upper keystone of the central arch for the entire duration of the fair, after being hoisted by means of a very complicated maneuver.

- Once the metal structure is built, it is time to install its cladding. At Ferrovial we make a 1:1 scale cut of the gateway to shape the wooden panels that are assembled with special couplers on the base structure. These panels are the stars of the gateway structure, painted by hand in harmony with each year’s design. This fits perfectly with the traditional character of the fair and seeks to maintain and dignify the craft trades.

- At the same time, a company contracted by Seville City Council installs some 25,000 LED bulbs in the panels. Its lighting kicks off the week of the fair and also marks the start of the countdown to choose the design of the following year’s gateway.

Ferrovial’s added value

The gateways and booths that brightened up the fairs of the first half of the 20th century were based on wood. However, a fire in 1964 destroyed more than a hundred booths, claimed the life of one worker and left many injured. From that moment on, the Seville City Council decided that the structures would be based on metal.

With this decision, Ferrovial Agroman’s history at the April Fair begins. The company was responsible for the design and assembly of these first metal structures and, in the same decade, patented a T-shaped part to make the connections between the tubes. Today, this part has been replaced by another tube coupler that is very common in scaffolding systems.

In recent decades, Ferrovial has left its mark at the fair. It has increased safety in the construction with the incorporation of safety nets and trays around the perimeter of the structure. The viability of integrating a fire protection mechanism in the gate facade itself is also currently being studied.

Every year, the Seville Fair welcomes millions of visitors. In 2023, more than two million people passed through the entrance gate to access the fairgrounds and welcome spring with a week of celebration that also bears the mark of Ferrovial.

Projects in Spain

SEE MORE

Renovation of the “Frontón Beti…

Drainage Cells for Eco Management in …

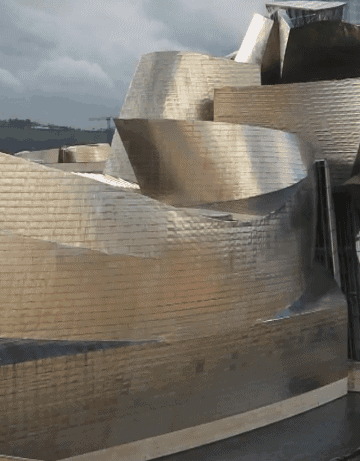

Guggenheim Museum

Plaza Mayor of Madrid

Piloting

Spain

-

2020

launch

-

10

aerial & ground robots

Most of the refineries and civil engineering infrastructures (bridges and viaducts) in Europe have been in use for more than half a century.

These pieces of infrastructure are wearing down due to aging, environmental conditions, increased load, changes in use, damage caused by human or natural forces, inadequate maintenance, or delayed repairs. They therefore urgently need new inspection, assessment, and repair strategies.

According to EU data, 330,000 rail bridges (66% of the total in Europe) are over 50 years old, and almost 60% of road or rail bridges (840,000 bridges) are made of concrete. In addition, some 55,000 of the 1.5 million bridges in Europe require continual inspection because of their criticality or age.

The European research project PILOTING promotes robotic technology to improve the inspection and maintenance tasks for infrastructure. For bridges alone, and working under the assumption that a third of these infrastructures can be inspected with robotic technologies, the potential market is around €70 million per year.

Specifically, the PILOTING platform will be evaluated in three scenarios: bridges, tunnels, and refineries. The first solutions to be validated within the project framework will be those relating to bridge inspection, with a solution based on aerial robots, which can take high-resolution images of the bridge/viaduct; these images will subsequently be analyzed by software based on artificial intelligence.

This technology, which is based on intelligent and highly autonomous robotic systems, allows inspection and maintenance operations to be carried out in less time, thus reducing costs, improving the quality of inspections by collecting and compiling real, reliable data from inspections, and finally, reinforcing the safety of the operators in charge of carrying out this type of visual inspections on bridges and viaducts. This examination is usually carried out by an operator who must work at significant heights, and it serves to reveal possible defects in the infrastructure (such as cracks, corrosion, delamination, water leakage, etc.).

Validation at the Arroyo del Espinazo Viaduct, Álora (Malaga)

Since its launch in January 2020, the PILOTING project has worked on the adaptation, integration, and demonstration of robotic solutions to increase the efficiency of inspection and maintenance activities in aging civil infrastructure. This set of technologies is composed of 10 aerial and ground robots, among them the robotic solutions that have been validated today at the Arroyo del Espinazo Viaduct in the Malagan town of Álora: AEROCAM, an aerial robotic platform for visual inspection, and VIAD- DRONE, an aerial platform that enables placing measuring devices on the infrastructure and obtaining more measurement information. The latter was validated today for the first time, while this was done for AEROCAM last April at the same viaduct.

Validating this technological solution is being spearheaded by CATEC, Ferrovial, and the University of Seville. The specific cases demonstrated today are:

- AEROCAM: general automated visual inspection of the infrastructure and detailed visual inspection of possible defects detected (CATEC).

- VIAD-DRONE: multifunctional drone for inspection with contact on viaducts (University of Seville)

- Other functions of VIAD-DRONE: installation of sensor box and visual inspection of neoprene (University of Seville)

- Presentation of Artificial Intelligence algorithms: analysis of inspection images using artificial intelligence (University of Seville)

- VIAD-DRONE and AEROCAM flight demonstration

The use of robotic technologies combined with Artificial Intelligence offers a set of advantages over a traditional inspection process. This is because the platform is capable of utilizing several robots, allowing workers to be supported in high-risk jobs, eliminating work at height, and providing greater information for decision-making, and this in turn allows for more regular inspections of critical infrastructures and industries.

This is the first test scenario where these technologies have been validated, but the PILOTING project includes other robotic solutions and new scenarios in other key industries such as refineries (in France) and tunnels (in Greece).

AIVIA – Orchestrated Connected Corridors

United States

-

2022

Project Year

-

€5-10 M

per Project

-

22miles

Sensored Highway

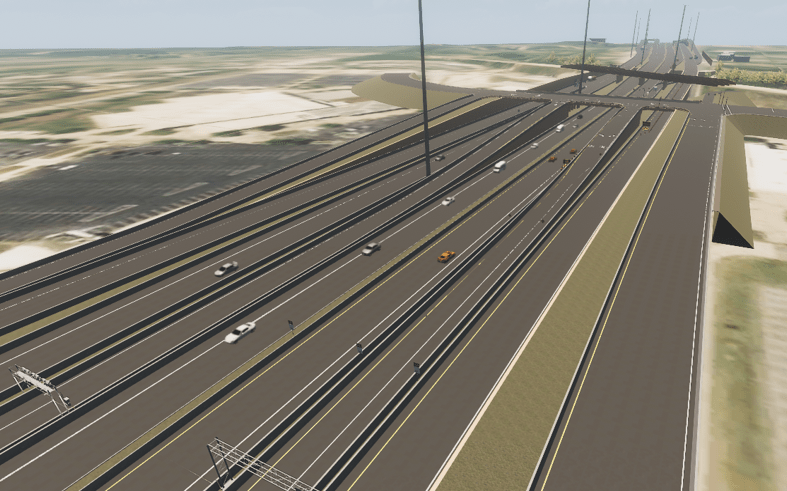

AIVIA’s main goal is to set the standard for the infrastructure and technology of the future in which conventional, connected and autonomous vehicles can co-exist harmoniously and that the maximum benefits of those technologies can be leveraged to maximize safety and traffic flow on our highways.

The initiative is presently testing new ways to build and implement the physical and digital infrastructure needed for the highways of the future – making the most of innovations such as Cellular Vehicle-to-Everything (CV2X), 5G, simulation technologies, advanced supervision and sensory technology to make roads more resilient.

AIVIA is aligned with Ferrovial’s Horizon-24 Plan, which aims to develop sustainable infrastructure with projects of high concession value, with North America being the key market for growth and development. The short term goal, partially achieved in 2023, was to apply all tested technologies on the I-66 corridor in Virginia to launch the first connected highway that shares safety information with vehicles and drivers real-time, with other assets following thereafter.

AIVIA is an initiative as a joint endeavour with global innovators

Testing Technologies and Providers

Cintra’s most prominent assets – North Tarrant Express Highway in Dallas and 407 ETR at Great Toronto Area, are the test beds for AIVIA to test new physical and digital solutions with our partners (3M, Kapsch , Microsoft, Telefónica and CapGemini). We are presently testing various technologies and providers under real traffic conditions to ensure a best-in-class efficiency of infrastructure, sensing devices and monitoring systems.

- In partnership with 3M, our teams are refurbishing segments of the road with a range of materials and solutions including retroreflective tape marking – four to five times brighter than now and visible in all driving conditions, which will become crucial to guarantee safe operation of autonomous vehicles under all conditions.

- As per the sensing hardware, we’re deploying new intelligent equipment such as lidar, radar and machine vision solutions to detect everything that happens on the road. The newer technologies like radar and lidar come to help, and complement the gaps that cameras can’t cover.

- However, the best sensors of the future will be the cars themselves. The Internet of Things (IoT) is a must to extend our digital fingers to all corners of the road. Indeed, the capacity of self-powered & self-connected sensors and actuators will support the digitization of our Highways and is key for controlling some very local events like car breakdowns, hits on the barriers or ice on the road.

- New communications systems will be deployed and will become part of the standard designs of new highways. New radio units will be installed to receive information and status from vehicles and also to broadcast electronic safety messages to connected vehicles (C-V2X) in real time.

- Dynamic messaging signals displaying accurate information for drivers to be aware of any risk event downstream will be placed along the Highway for conventional vehicles turning our corridors into true – digital highways.

Many technologies are getting stressed under real traffic conditions, with the ultimate objective for AIVIA to select only the more reliable and scalable, which will finally integrate with the core of the system: the software platform that orchestrates all vehicles by sharing the right information at the right moment with the right actors.

How Does AIVIA Bring Value?

The AIVIA initiative is helping to maximize the utility that CAVs and other cutting edge technologies can bring while providing benefits for all road users of today. AIVIA aims to define the blueprint of the sustainable infrastructure of the future for mixed traffic, using cutting edge technology to make travel safer, journey times more reliable and adding value to highway users through enhanced connectivity and the services that come with it.

Related Projects

See more projects

I-66 Outside the Beltway, VA

North Tarrant Express, TX

407 ETR

Behavioral Economics

Real-Time Propensity Factor

VR Highway Simulation

United States

-

+2

KMs to be VR-Driven

-

100.000

€ PoC Cost

-

4

Managed lanes

The goal of this project is to demonstrate the applicability of VR Driving Simulation functionalities in a realistic 3D digital model of a highway environment to assess efficiencies and risks, from design reviews to stakeholder’s engagement as O&M

The “PoC VR – Highway Simulation” project falls under the umbrella of the whole-life digital asset program which the Department of Asset Management and Process Digitalization is leading within our company. The digitalization of the built asset industry represents an enormous opportunity for innovation for our infrastructure and highways projects, airports, power infrastructure and autonomous vehicles.

Project objectives

- Development of a 3D virtual model with enough realism and accuracy based on actual assets. For this project, the North Tarrant Express located in Fort Worth, Texas, USA, was modeled based on opensource information

- Development of a Virtual Reality environment incorporating all the 3D models in which the user can immerse and drive thanks to some external equipment (steering wheel, pedals, VR glasses headset)

- Integration of an external traffic management simulator into the VR environment (Sumo)

- Design of a traffic diversion incorporated in the VR environment including impacts to traffic

- Development of real-time functionalities to add objects to the scene to recreate different scenarios

Value of the solution

- Knowledge transfer and skillset development within our engineering teams.

- Generation of virtual environments based on real infrastructures suitable for virtual simulations.

- Comprehension of the interactions between the user and the surrounding context of assets for data collection linking into behavioral economics initiative.

- Instantaneous adaptability to different scenarios and changing situations.

- Improved highway design and development system for better a performance and a more fitting user experience.

Related Projects

See More Projects

Barranco de Erques Arch Viaduct

407 ETR

C-Roads Platform

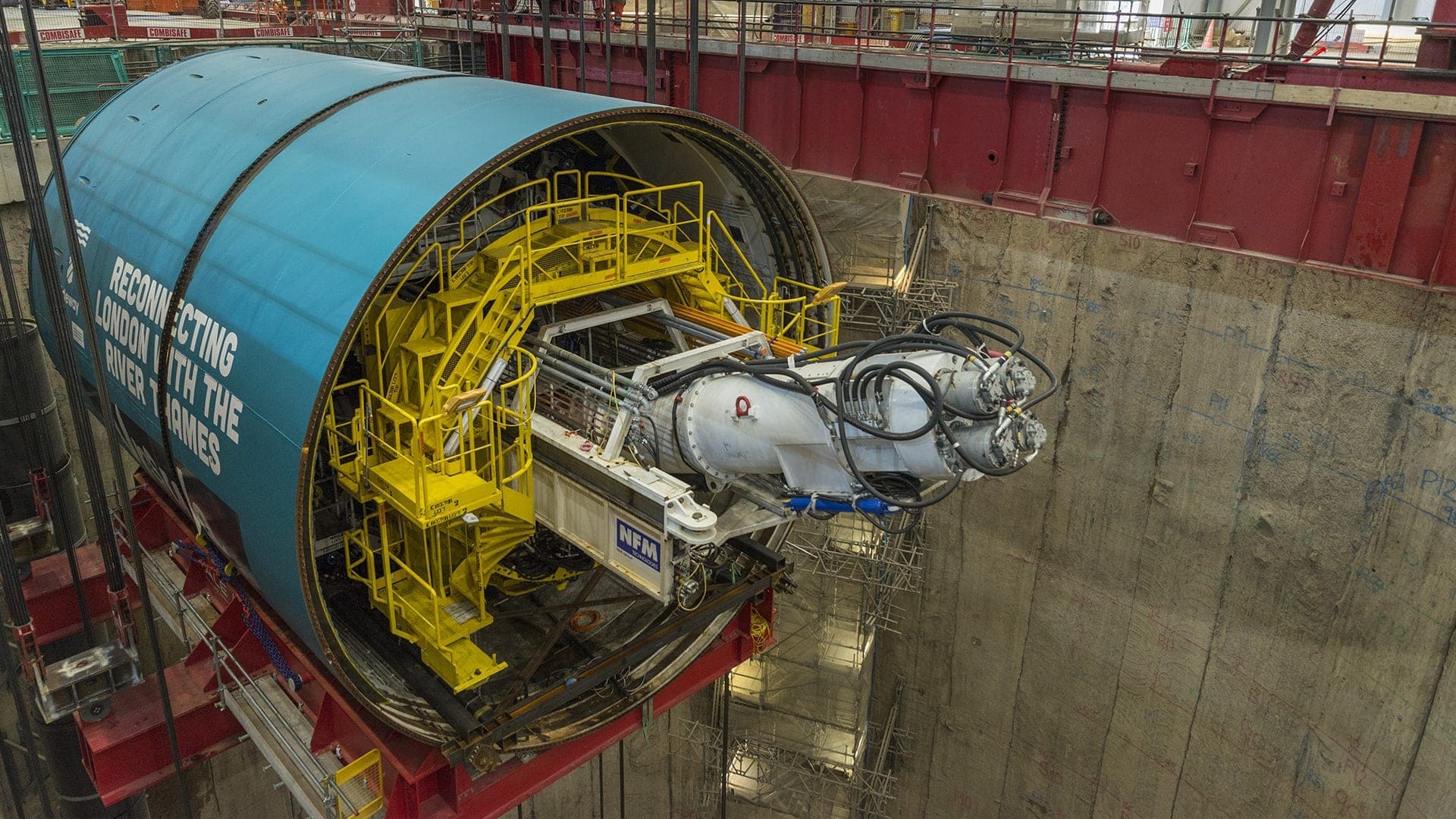

Thames Tideway Tunnel, Central Section

London, United Kingdom

-

£1.5bn

Budget

-

12.7km

New Sewer Tunnel Length

-

Reduction

95%In Sewage-Related Waste

-

9000+

Jobs Created

The Thames Tideway Tunnel is the largest infrastructure project ever undertaken by the UK water industry. It is essential to tackling overflows from London’s Victorian sewers into the Thames for at least the next 100 years. The project will create over 4,000 sustainable jobs and another 5,000 indirectly. It will also offer hundreds of local apprenticeships and work placements, leaving a lasting legacy in the heart of London.

London’s sewerage system relies on a series of combined sewer overflows, designed to discharge into the Thames during heavy storms. This system releases sewage into the river on a weekly basis, reaching over 55 million tonnes annually. We are delivering the central section while working alongside two other contracting teams in the west and east. Our scope includes development consent, design, and construction of the new sewer tunnel.

With a total length of 12.7km, the central tunnel will be driven using two purpose-built 8.8m diameter Earth Pressure Balance (EPB) TBMs, and will run up to 60m deep between Fulham and Bermondsey. In addition, the works include the construction of eight shafts and pumping stations, logistics, and soil disposal via the barges on the river.

Collaboration is a key factor for successful delivery. We have established a Procurement Alliance, in collaboration with Thames Water, the different Main Works Contractors, and the System Integrator (Amey) to ensure that a best-for-project approach is consistently followed. This effective approach to risk management and mitigation ensures that the project is delivered to the highest standards.

Added Value

- Consistent approach to design optimisation and value engineering to reduce cost and improve efficiency

- Use of the River Thames for transport and logistics to minimise movements by road, including TBM sections delivered by river and 2.7million tons of TBM spoil removed

- The Legacy Programme will benefit ecology, public health, the environment and the appearance of the Thames through formal commitments on five key themes: environment, health and safety, economy, people, and places

- Innovative implementation of hybrid cutting wheels on the hydromill to increase production and improve efficiency for the integral diaphragm walls

Over 3,000 authorizations achieved seven months ahead of schedule.

Thames Tideway Tunnel | Ferrovial

Related projects

See more projects

Heathrow Post T5 Transfer Baggage Tunnel

Crossrail

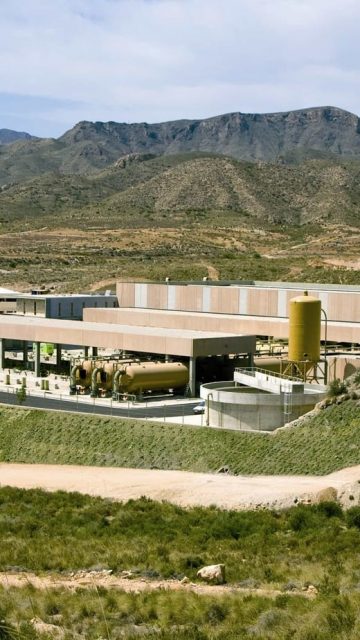

Desalination Plant Al Ghubrah Oman

Valdelentisco Desalination Plant

Mixed Arch “Monastery Bridge” on the M-50 in Dublin

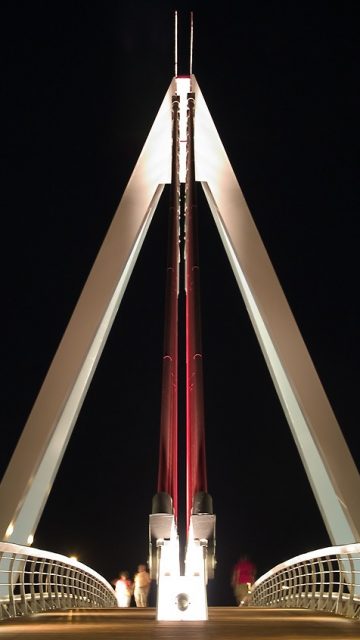

Dublin, Ireland

-

€102.01 M

Total Budget

-

1550t

Weight

-

62m

Length

As part of the expansion that our construction subsidiary Ferrovial Construction carried out on Dublin’s M-50 beltway, the S04 structure is a mixed arch bridge located at the junction of the M-50 and the N-7 that connects Monastery Road and the lightrail tram station by crossing the N-7.

The 62-meter-long bridge consists of two parallel vertical arches 15 m high that are unbraced and separated by 14 m between axes. The arches are formed by steel tubes with an almost rectangular cross-section and filled with self-compacting concrete.

The deck is 20 m wide, which allows for two lanes of vehicular traffic and two bicycle lanes, in addition to two cantilever sidewalks along the outside of the arches. The structural section is composed of two longitudinal box girders made of steel braced by transverse double-T beams. The deck slab is made of reinforced concrete 25 cm thick. The deck is connected to the arches on the spring lines by means of 8 pairs of suspension cables made of locked coil cable 63 mm in diameter.

The main condition for executing this structure comes from the need to not affect existing traffic, along with the little space available. As such, manufacturing began on the metallic structure in a workshop, while work was done on the foundation, the abuttment, and the preparation of auxiliary launch pieces at the construction site. Assembly was done on-site on a platform adjacent to the southern abuttment, where there are two slabs where slide rails are located. Launching the entire bridge, with its 1,550 tons of weight, to the final site was carried out with special trucks located at the far front end and sliding devices at the other end. The nighttime operation was done while interrupting traffic for only 3 hours.

Related projects

see more projects

Harwood Bridge, Pacific Highway Upgrade

Suspension Bridge on the A-6 in Madrid

Arch of Los Tilos

Montabliz viaduct

Barranco de Erques Arch Viaduct

Renovation of the “Frontón Beti Jai” Building, Madrid

Madrid, Spain

-

10800m²

Floor area

Located at no. 7 Marqués de Riscal Street in Madrid, construction began in 1893 using state-of-the-art techniques and materials at the time. It is listed as a singularly protected building, lies on a 3,609 m² plot of land, and has a floor area of 10,800 m². The work done was ultimately aimed at recovering the Beti Jai court’s architectural beauty and making the building compliant for public use.

History of the Beti-Jai

Since it was completed and until the year 1918, this building was used as a playing court. From 1919, it was used for various purposes such as a garage, police station, prison and plasterboard items workshop. In 1977, the building was in a state of neglect. Because of its history, the purposes for which it was built, and for its blend of eclectic and Neo-Mudéjar styles, the Madrid Institute of Architects drew up a report to apply for conservation and public use of the building. In 1991, it was listed as a National Monument and, thereafter in 2011, as a Cultural Interest Asset.

The eclectic-style façade at no. 7 Marqués de Riscal Street is currently the only visible element from the outside. The building is elliptical in shape and what is striking about the inside is the Neo-Mudéjar-style curved side façade, its cast-iron columns, and the curved beams supporting the grandstands which ensured court visibility from any angle.

Time had taken its toll on the empty building and, in order to mitigate the damage, our construction subsidiary Ferrovial Construction undertook various renovation works for Madrid City Council’s Heritage Directorate General.

Renovation process

At a first preliminary stage, the following work was done:

- Applying urgent measures including protective scaffolding on the main façade, which was also used to study it closely, and generally propping up the building.

- Gathering information. Planimetric and topographic maps were produced, indicating the true structural situation, bulging walls, cracks, etc. and a sewerage study was also conducted.

- Analysis of the condition of the structure and the foundations by taking samples and carrying out tests to check the extent of support provided by the building’s load-bearing walls, condition and dimensions de girders, walls, etc.

Having established the advanced state of dilapidation resulting from years of neglect and zero maintenance, structural consolidation and rooftop waterproofing work began in July 2016. Consequently, all elements at risk of collapsing and potentially affecting other elements which could conceivably be recovered and restored were removed.

The work done was ultimately aimed at recovering the Beti Jai’s architectural features without altering its essence. At the same time, the project wanted to meet the necessary requirements for a building that is currently being used by the public to be compliant. That is why structural consolidation was carried out to achieve a suitable load increase for that use. The foundations were therefore reinforced to receive the necessary elements capable of absorbing such loads without causing a glaring change in the extremely characteristic aesthetic features of the court. Wall uprightness was also recovered on the inside to guarantee wall stability.

As for the outside, the façade onto Marqués de Riscal has been recovered not only insofar as its composition is concerned, but also in regards to its aesthetic features and original finish. This means that all partly remaining elements have been recovered, including parts of or complete coats of arms, corbels, pilasters, banisters,etc. In short, all elements that made up the façade have been restored in order to proceed to make moulds and reproduce the same items. Work has been slow and thorough given the condition it was in and the requirement that the façade be recovered as it was originally conceived by Joaquín Rucoba. The same procedure was applied to all other façades.

The top banister—which had completely disappeared—was also recovered and so was the buttress with the name Beti Jai on it. In order to recover the letters, the original letters partly remaining on the inner façade were used, scaling them up to precisely twice their size.

The original layout of all the other façades has been recovered, along with their materials, manually replacing lost bricks one by one, and then pointing and protecting the same.

All non-original elements, such as grandstand partition walls, were eliminated in order for the original ironwork, which was cleaned and protected, to be visible again.

As for the roofs, they have been returned to their original condition, including lambrequins and wooden roof-end elements on the inside of the grandstands.

While the delicate and painstaking works were under way, all constructive elements found were analysed and checked to see whether or not they were original in order to eliminate all elements having an adverse impact. An example of this work was the discovery of the original, characteristically shaped roof tiles in the main body dating back to the year 1894, supplied by the Great Tile Factory of Eloy Silió. Molds were made to manufacture new tiles and lay them out in order for the roof to recover its original condition.

Similarly, the existing wall tiles have been dated, numbered and stored.

3-D modelling techniques applied to the Beti-Jai

Laser scanning was used to map the building for all of these works to be carried out, and a 3-D model of the building was also obtained. These techniques allowed all elements to be dimensioned with millimetric precision.

All of these works carried out have allowed a unique building to be recovered and restored.

Related projects

See more projects

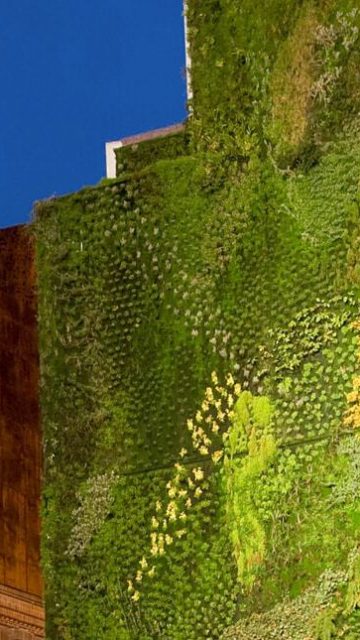

Caixa Forum Madrid

Guggenheim Museum

Puerta de América Hotel

Marqués de Riscal Hotel

Pavement Restoration on the 18L-36R Runway at the Adolfo Suárez Madrid-Barajas Airport

Madrid, Spain

-

€+10M

Total Budget

-

70000t

Flexible Pavement

-

24h/5d

Time Spent on Project

-

+130

Trucks

The restoration construction on the pavement on the 18L-36R runway and surrounding taxiways at the Adolfo Suárez Madrid-Barajas Airport, along with construction to eliminate obstacles on that track, were awarded to Ferrovial Construction in 2016 for over €10 million.

Our construction subsidiary Ferrovial Construction took up quite a challenge with this project, since it required working on the runway for a record 24 hours a day for five consecutive days, regenerating 70,000 tons of flexible pavement. To do so, it had 11 milling machines, 4 asphaltic agglomerate plants (two of which were installed by the Machinery Service inside the Airport), 10 asphalt spreading crews, and over 130 trucks.

The project also includes 240 kilometers of primary guidewires, 21 kilometers of secondary wire, and 2,000 buoys installed. The state of the runway fringes were also improved, and more than 2,000 elements, such as catch basins, signaling, underground galleries, and more have been updated.

The 18L-36R runway is 3,500 meters long and 60 meters wide, and it went into service in 2006. Aena tackled this job before the useful life of the infrastructure ended, thus proactively addressing situations that could have compromised the airport’s operational capacity. The runway’s performance in terms of operational capacity was planned and coordinated beforehand with operators and Enaire, the aerial navigation service provider, so that it was possible to do so and not impact the airport’s normal operations.

This project did have one more variable that turned out to be a critical one: the south wind, since airplanes had to land on the runway under construction with this wind. For this reason, planning had to be adjusted to the max in order to carry out the construction in a short window without the south wind and with the ever-present risk of needing to stop construction and get the runway operational in the middle of construction. After several attempts and last-minute cancellations, construction began on Friday, May 19, 2017, at 5:00 p.m. and ended on Wednesday, May 24, at 11:00 a.m., when the runway and surrounding taxiways opened to traffic.

Related projects

See more projects

Heathrow Airport

Glasgow Airport

LBJ Highway in Dallas, Texas

Southampton Airport

WUH Port of Galveston Cruise Terminal 2 Expansion, TX

Galveston, US

-

150000

Square Feet

-

2000

Passengers

-

$11M

Budget

Modify and expand the two-story terminal at Port of Galveston Cruise, the 4th busiest cruise port in the U.S.

The port worked closely with Royal Caribbean to identify upgrades needed to improve operations at Cruise Terminal No. 2 for both Voyager class vessels and any larger vessels in the future.

Our brand Webber was awarded the contract to modify and expand the two-story terminal. Work features 150,000 square feet of space and terminal seating capacity of over 2,000 passengers (from only 700). The westward expansion and modification of the Cruise Terminal 2 structure includes: converting the passenger check-in area to a baggage lay-down area and modifying the east end of the building to facilitate passenger and baggage screening activities with the ultimate goal of designing and building the expansion so that it will be incorporated into a new Terminal 3 at a later date.

All existing services that were upgraded or added, including power, electrical, telecommunication, security, HVAC and mechanical, sewage, potable water as well as improvements to the adjacent uplands area were performed so as not to disrupt current terminal users. During the project, we held weekly meetings with the port to identify work areas needed for action to keep on schedule and request port authorization. In some cases, we erected temporary screen walls to keep passengers clear of construction work areas and maintain aesthetics. In all cases, we kept the construction areas clean of debris before a ship arrived. And even though the cruise schedules were well published, Webber continuously coordinated with the port to ensure there were no last minute changes or misunderstandings.

The port of Galveston, Texas’ Star Cruise port serves as the primary point of embarkation for cruises to the Caribbean and Bahamas and each year handles over 1 million cruise passengers, making it the 4th busiest cruise port in the U.S.

Related projects

See more projects

Port of Galveston Pier 16 Extension

North Tarrant Express, TX

LBJ Expressway, TX

I-66 Outside the Beltway, VA

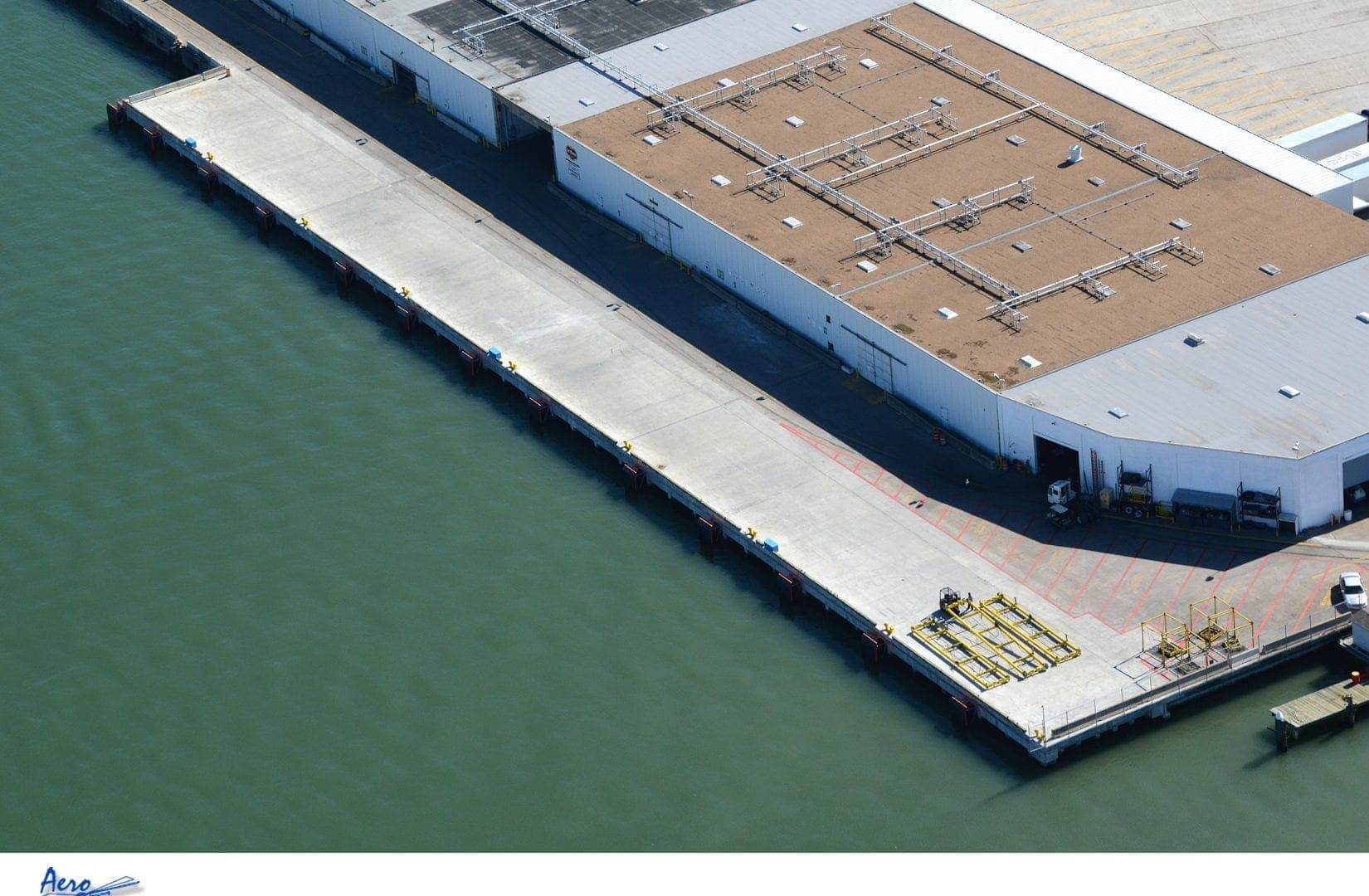

WRK Port of Galveston Pier 18 Wharf Extension, TX

Galveston, Texas

-

$5.2M

Cost

Rehabilitation project for Port of Galveston. The project was being partially funded by a $10 million Disaster Assistance Grant Program from the U.S. Department of Commerce’s Economic Development Administration (EDA), which came to the aid of the port after Hurricane Ike.

The first phase of the construction project, which involved expanding the dock apron an additional 40 feet further into the channel and installing improved fendering and moorings was completed at a cost of $5.2 million.

These renovations enabled Del Monte to more efficiently discharge cargo from ships calling at the terminal. The Port of Galveston, Texas’ Star Cruise Port, serves as the primary point of embarkation for cruises to the western Caribbean and the Bahamas. Four cruise lines, Carnival Cruise Lines, Disney Cruise Line, Princess Cruises and Royal Caribbean, sail from Texas’ only cruise port.

-

Construction after Hurricane Ike

Related projects

See more projects

LBJ Expressway, Dallas, TX

I-77 Express Lanes, NC

I-66 Highway, VA