Each project and asset is legally independent and has its own managers.

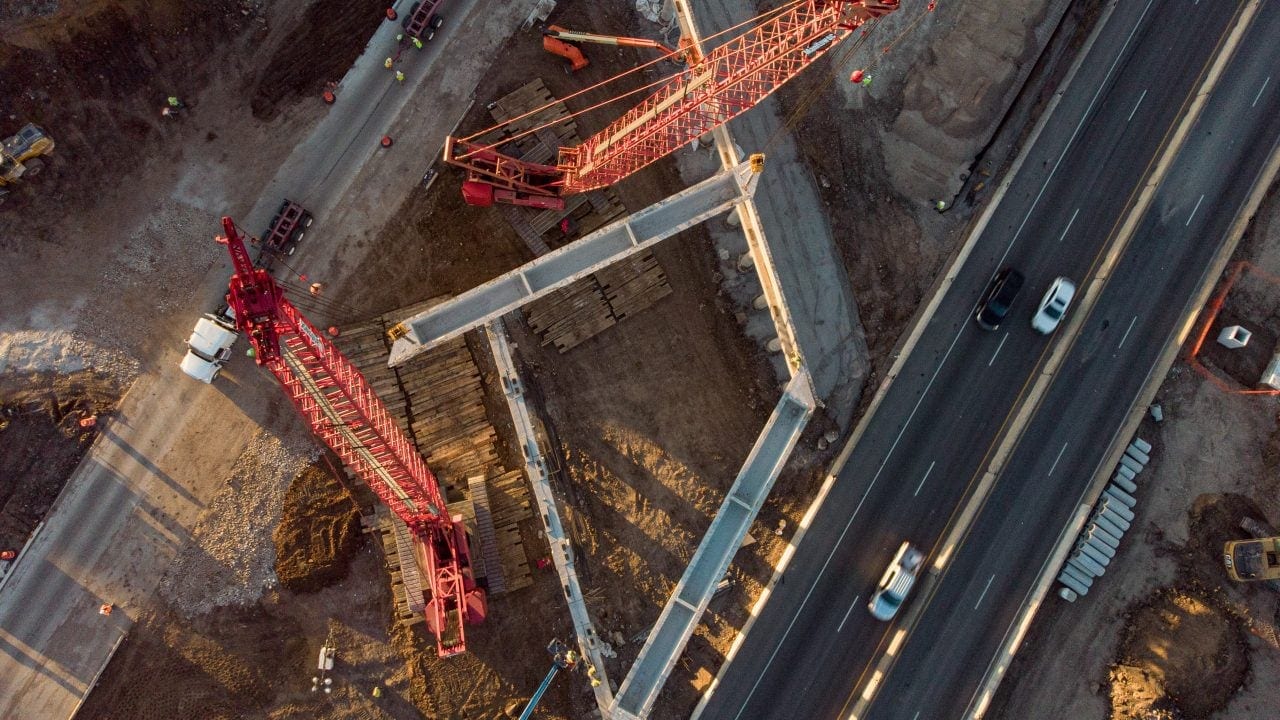

IH 35 Rehabilitation

The project involves reconstruction of 6.7 miles of IH 35 in Waco, TX. The project was bid at $341 million and is the largest hard bid project to be awarded in Webber’s history.

The project scope of the rehabilitation of IH 35 consists of widening and reconstruction of 6.7 miles from Craven Road to 12th Street in Waco, Texas. The contract includes construction of 24 bridges, the removal of three existing concrete main lanes in both directions, replacement with four lanes of 15” continuously reinforced concrete pavement – north and southbound – and reconstruction of the existing concrete frontage roads.

In addition, the project includes the installation of more than 132,000 linear feet of reinforced concrete box culverts and pipe, electrical, concrete flatwork, landscape, irrigation and pavement markings throughout the corridor.

Special Features

One of the challenges that the project team faces is the work over the Brazos River and the need of using barges and bulkheads (sheet-pile and compacted earth setup to form a work dock) as a mean to provide stable work surface, for both man and equipment. A special Safety plan was needed for these water operations, first to address the safety of the employees, but also the impact that construction in this area has for the environment and recreation on the river.

For example, all barges must be engineered to ensure that the requirements of stability are satisfied, taking into consideration the type of equipment operated on the barges and their working radius. Cranes are most affected by this as their swing radius and the weight of their loads are much greater than any other equipment used on the barges. As a crane swings its load, it will apply forces to the barge in variable areas that may cause the barge to dip down in the water. This dipping is referred to as “List” (dipping to the lateral sides) and “Trim” (dipping to the frontside). Webber monitors the List and Trim with a “List & Trim Monitor” that is mounted in the cabin of the crane with sensors attached to the body of the crane. This monitor helps the team keep within the maximum allowable tolerances of List and Trim that are outlined by Crane Manufacturers, OSHA and ASME.

Another significant challenge is that the project is located near the Baylor University campus. Due to the heavy traffic flow and adjacent retail and residential along right-of-way, the project is working during restricted hours and lane closures to minimize the impact to the traveling public and local businesses.

Due to the size of the project, over 25 crews and various subcontractors work at the same time in the different areas. Also, 25 engineers and 4 superintendents supervise and coordinate the job.

The schedule, the pace, the amount of people and the size of the job make this project truly a challenge. But we are working hard as a team, making sure we are all helping each other achieve our milestones, our finish dates. Everyone is cooperating with the client, with the subcontractors, and with other crews.

Paloma Fernandez, Senior Project Manager.