Each project and asset is legally independent and has its own managers.

Post-Tensioning in Structures

Post-Tensioning in bridges built in formworks

Nowadays, most Civil Engineering works include multiple structures, such as overpasses and underpasses, which are usually executed on formwork. The use of Post-Tensioning techniques is crucial for the construction of this type of structures, which are built on site with the following main advantages:

- Reduced costs

- Larger spans

- Smaller deck depths

- Elimination of joints

- Greater durability

These structures can be executed in one or multiple phases, depending on their length. We offer many different solutions that cover all post-tensioning requirements for this type of structures: Anchors, from 1 to 37 0.6”, Continuity anchors, Active and passive anchors, Vertical and horizontal tendons used to join abutments, Adjustable anchors and Cement, wax or grease grout injections.

Post-Tensioning in bridges in self-launching formworks

Nowadays, Civil Works viaducts are built with larger spans and at greater heights. Therefore, the construction techniques have been improved with the use of Self-lifting Formwork Structures, Hoisting Carriers and Assembly Techniques. Self-lifting formwork is a device that lifts and transports the exterior and sometimes interior slipform, supporting itself on the pile without any dismantling until the structures are finalized. With this system, sustained performance of up to a span of 50 m per week is achieved.

With these structures, the post-tensioning execution timing between spans is essential. If pouring is not completed, there is no continuity between spans and tension is performed too quickly, an imbalance is created in the weekly work cycle and can result in the loss of the structure. We use fully automated processes to carry out essential tensioning tasks that ensure, or may even improve, expectations for construction.

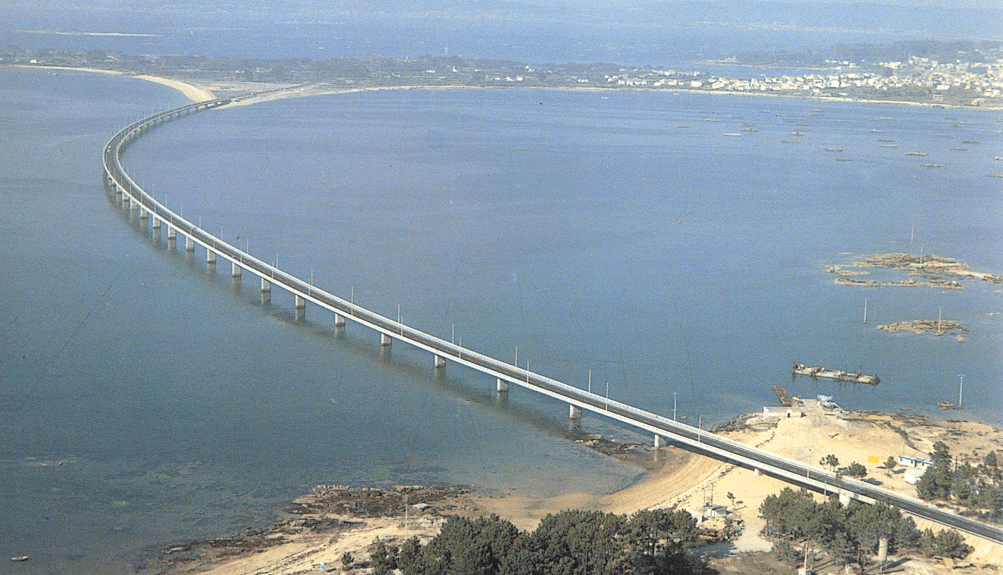

Post-Tensioning of precast segment viaducts

We are the most experienced company in the precast segment viaduct tensioning market. This type of viaduct has a deck made of sections measuring approximately 2.4 m, referred to as segments, which are then set in place with the hoisting carrier.

The segments are first placed on the pile section and then advance in a T-shaped projection until they meet the corresponding T-shaped projection of the next pile.

Logically, segments are joined with post-tensioning operations. Sometimes, to facilitate hoisting operation performance, exterior Pretensioning operations are available in the second phase, which will be responsible for absorbing the service loads.

The execution of tensioning operations for this type of viaduct is highly complex due to the following:

- Post-tensioning is regarded as the critical path to hoist the next segment. This is how 10 segments can be hoisted per launcher and per day.

- When it comes to viaducts with variable depths, space to execute tensioning operations is limited. There can be less than 1.20 m of space in these types of viaducts. This is why we have developed special tools to attain high performance in small spaces.

- There are hazards involved in tensioning when working in such a small space.

Post-tensioning in balanced cantilever viaduct

This construction method is based on formwork carriers that move in cantilever form from both sides of the piles in 3- to 10-meter segments. This method is used for viaducts with large spans, when no other type of construction technology can be used.

We performed post-tensioning on the Pujayo and Montabliz Viaducts on the Cantabria-Meseta highway, among others. Pesquera-Molledo segment. Specifically, the Montabliz Viaduct has one of the largest piles and spans in Spain and is constructed with 10-meter long segments and post-tensioning with tendons of 31 0.6” up to 162 meters long.

We carried out post-tensioning of these works using the resources necessary to achieve superior performance in terms of segments per week and pile.

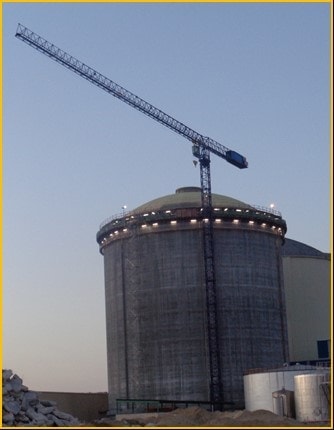

Post-Tensioning in special structures

The use of Post-tensioning operations is vital in the construction of special structures, such as:

- Water tanks

- Waste water digesters

- Silos

- Liquefied Gas Tanks

- Nuclear Power Plants

- Telecommunications Towers

- Surge tanks

These structures require a strict quality control process and perfect execution. We have a wide range of experience in this type of work.

Post-tensioning operations in building works

There are many advantages to using Post-tensioning in Building Works:

- Cost savings

- Large open spaces

- Greater distance between piles

- Smaller slab depths

- Lower number of joints

- Control of deflections

- Smaller foundation structures

- Greater durability

We have carried out the post-tensioning operations of many slabs in different types of singular buildings such as shopping centers, hotels, conference centers, train stations, airports, universities, etc. We have used different solutions in these projects, from non-adherent single-strand systems to 31 0.6” tendons, passing through 4 0.6” units with plain duct.

Installation of bearing trumplates and ducts

The bearing plates of the trumplates are anchored to the formwork structure with cases, in order to guarantee the correct alignment of active frameworks during start-up, leaving the minimum clearance dimensions needed to insert the hydraulic jack after the formwork removal operations. Ducts and steel fixings are installed at the same time. Said operations comply with the specifications described on the plans, supporting these elements on the passive framework every 1 or 2 meters, depending on the complexity of the layout and the unit used.

Joint couplers are used to fix ducts. Said joints are sealed with tape to prevent grout from being poured inside during the concrete pouring operations. Special parts (vents) are installed on the highest points. These include a plastic tube that allows the discharge of air to the exterior during injection operations, to make sure that there are no air pockets inside the duct.

Strand threading

This operation is, when possible, carried out before concrete pouring operations in order to prevent the risk of potential dents or cracks of the duct, which would prevent the execution of the threading operations.

After assembling the coil on the strand, the reel is aligned with the alignment unit. A bullet-shaped metallic piece is installed on the edge of each wire to prevent deflection effects and damage to the duct. One of our experts threads the strands as required by the project for subsequent tensioning operations.

Tensioning of the tendon

After the concrete pouring and formwork removal operations, one of of our experts installs the anchor heads and wedges. The tensioning process starts when the adequate concrete resistance value has been reached and has been confirmed by the corresponding compression test. Said situation is reported by the Site Management Area to one of our experts. The tensioning process is carried out in compliance with tensioning program instructions, which are designed and drafted at our offices beforehand and include the following:

- Partial tensioning stages.

- Tensioning order in each stage.

- Anchor tensioning of each tendon.

During tensioning operations, the expert records the different load steps and elongation that has taken place during the operation in the corresponding report. The measurement equipment will be adequately calibrated. Likewise, elongations will be measured with a minimum precision of 2% of the total length.

Cutting edges and sealing cases

After tensioning operations are completed and the elongations have been checked, the corresponding supervisor gives instructions to cut the tensioning edges with a radial saw, 3 cm from the edge of the wedges. The cases will then be sealed with a non-shrink grout. The tubes used for injection are placed before sealing the cases, connecting them to the openings on the bearing plates.

Grouting

The conduits are washed with water before the grouting process, which eliminates all water-soluble oils during the threading operations and discharges the remaining water by injecting compressed air. In case no oils have been used, cleaning operations can be carried out with injected air. In addition, cleaning operations can be used to detect possible obstructions and connections between ducts or between ducts and recesses. The grout injection process requires the use of a 3 to 5 m3 per hour capacity grout injector, with a double mixer, designed so as to prevent any interruptions during the operations. The injected grout has the following composition: 100 kg of cement, TYPE I, 40 to 43 L of water and 450 g of additives.