United States

-

2022

Project Year

-

€5-10 M

per Project

-

22miles

Sensored Highway

AIVIA’s main goal is to set the standard for the infrastructure and technology of the future in which conventional, connected and autonomous vehicles can co-exist harmoniously and that the maximum benefits of those technologies can be leveraged to maximize safety and traffic flow on our highways.

The initiative is presently testing new ways to build and implement the physical and digital infrastructure needed for the highways of the future – making the most of innovations such as Cellular Vehicle-to-Everything (CV2X), 5G, simulation technologies, advanced supervision and sensory technology to make roads more resilient.

AIVIA is aligned with Ferrovial’s Horizon-24 Plan, which aims to develop sustainable infrastructure with projects of high concession value, with North America being the key market for growth and development. The short term goal, partially achieved in 2023, was to apply all tested technologies on the I-66 corridor in Virginia to launch the first connected highway that shares safety information with vehicles and drivers real-time, with other assets following thereafter.

AIVIA is an initiative as a joint endeavour with global innovators

Testing Technologies and Providers

Cintra’s most prominent assets – North Tarrant Express Highway in Dallas and 407 ETR at Great Toronto Area, are the test beds for AIVIA to test new physical and digital solutions with our partners (3M, Kapsch , Microsoft, Telefónica and CapGemini). We are presently testing various technologies and providers under real traffic conditions to ensure a best-in-class efficiency of infrastructure, sensing devices and monitoring systems.

- In partnership with 3M, our teams are refurbishing segments of the road with a range of materials and solutions including retroreflective tape marking – four to five times brighter than now and visible in all driving conditions, which will become crucial to guarantee safe operation of autonomous vehicles under all conditions.

- As per the sensing hardware, we’re deploying new intelligent equipment such as lidar, radar and machine vision solutions to detect everything that happens on the road. The newer technologies like radar and lidar come to help, and complement the gaps that cameras can’t cover.

- However, the best sensors of the future will be the cars themselves. The Internet of Things (IoT) is a must to extend our digital fingers to all corners of the road. Indeed, the capacity of self-powered & self-connected sensors and actuators will support the digitization of our Highways and is key for controlling some very local events like car breakdowns, hits on the barriers or ice on the road.

- New communications systems will be deployed and will become part of the standard designs of new highways. New radio units will be installed to receive information and status from vehicles and also to broadcast electronic safety messages to connected vehicles (C-V2X) in real time.

- Dynamic messaging signals displaying accurate information for drivers to be aware of any risk event downstream will be placed along the Highway for conventional vehicles turning our corridors into true – digital highways.

Many technologies are getting stressed under real traffic conditions, with the ultimate objective for AIVIA to select only the more reliable and scalable, which will finally integrate with the core of the system: the software platform that orchestrates all vehicles by sharing the right information at the right moment with the right actors.

How Does AIVIA Bring Value?

The AIVIA initiative is helping to maximize the utility that CAVs and other cutting edge technologies can bring while providing benefits for all road users of today. AIVIA aims to define the blueprint of the sustainable infrastructure of the future for mixed traffic, using cutting edge technology to make travel safer, journey times more reliable and adding value to highway users through enhanced connectivity and the services that come with it.

Related Projects

See more projects

I-66 Outside the Beltway, VA

North Tarrant Express, TX

407 ETR

Behavioral Economics

Real-Time Propensity Factor

Aberdeen Airport places its bets on Artificial Intelligence to maintain its runways

Aberdeen, United Kingdom

At Ferrovial Airports we go a step beyond the standards for airport pavement inspection by performing pilot tests that incorporate an artificial intelligence tool to check the condition of runways and taxiways at Aberdeen Airport.

The condition of the pavement at runways and taxiways is one of the key factors to ensure the safe and efficient performance of airport operations. In addition to having a direct impact on the safety of passengers and workers, any pavement anomaly could generate additional costs and hinder the operation of an airport

Currently, the International Civil Aviation Organization (ICAO) and other Regulatory Bodies establish a minimum pavement inspection process shared by all airports, so it is the responsibility of each operator to increase the frequency and depth of the inspection.

Artificial intelligence to control and prevent possible risks on runways

To control and anticipate possible risks related to runway conditions, Aberdeen Airport has committed to artificial intelligence in a pilot program carried out over the course of 9 months.

To try to control and anticipate the possible risks linked to the conditions of the runway, we have opted for artificial intelligence in a pilot program carried out for 9 months. We opted for the use of a tool that would reduce and operate in maximum safety conditions.

The purpose of VIOMINER, the name given to this initiative, is to strengthen the manual inspection carried out by airport professionals.

This solution was developed in cooperation with Vaisala – a Finnish company that develops, manufactures, and commercializes products and services for environmental and industrial measurements- and with the team at Aberdeen Airport.

Up till then, our technicians specialized in identifying the possible bad condition of the pavement divided their inspections into three levels:

- A first inspection done by technicians in a vehicle twice a day.

- The second one, which is carried out by managers on foot once a month.

- A third phase done by managers and consultants on foot twice a year.

With a mobile app and web-based platform, the new tool with Computer Vision and Artificial Intelligence can identify anomalies such as cracks, abrasion, and potholes, increasing the effectiveness of level 1 and 2 inspections.

During level 1 and through a cell phone integrated into the vehicle, VIOMINER records the runway as it travels. The data collected is loaded into the system and processed. Artificial Intelligence algorithms recognize anomalies in the pavement and create a heatmap of the paths visited.

During level 2 inspections, the manager carries out a more qualitative study of a anomalies by sending a photo and the exact location of the spot by GPS.

All of this information, along with what the professionals have already collect, enables the generation of reports for each anomaly. These are then summed into the data and into a satellite map, which allows register of historical data and creating reports faster and timely manner.

This solution is a clear example of how innovation and new technologies can help improve the operational and economic performance of airports and, above all, demonstrate how anticipating risks can be a competitive advantage in the future.

Related projects

see more projects

Aberdeen’s biggest transformationProject

Heathrow Airport

Glasgow Airport

Southampton Airport

Aberdeen Airport

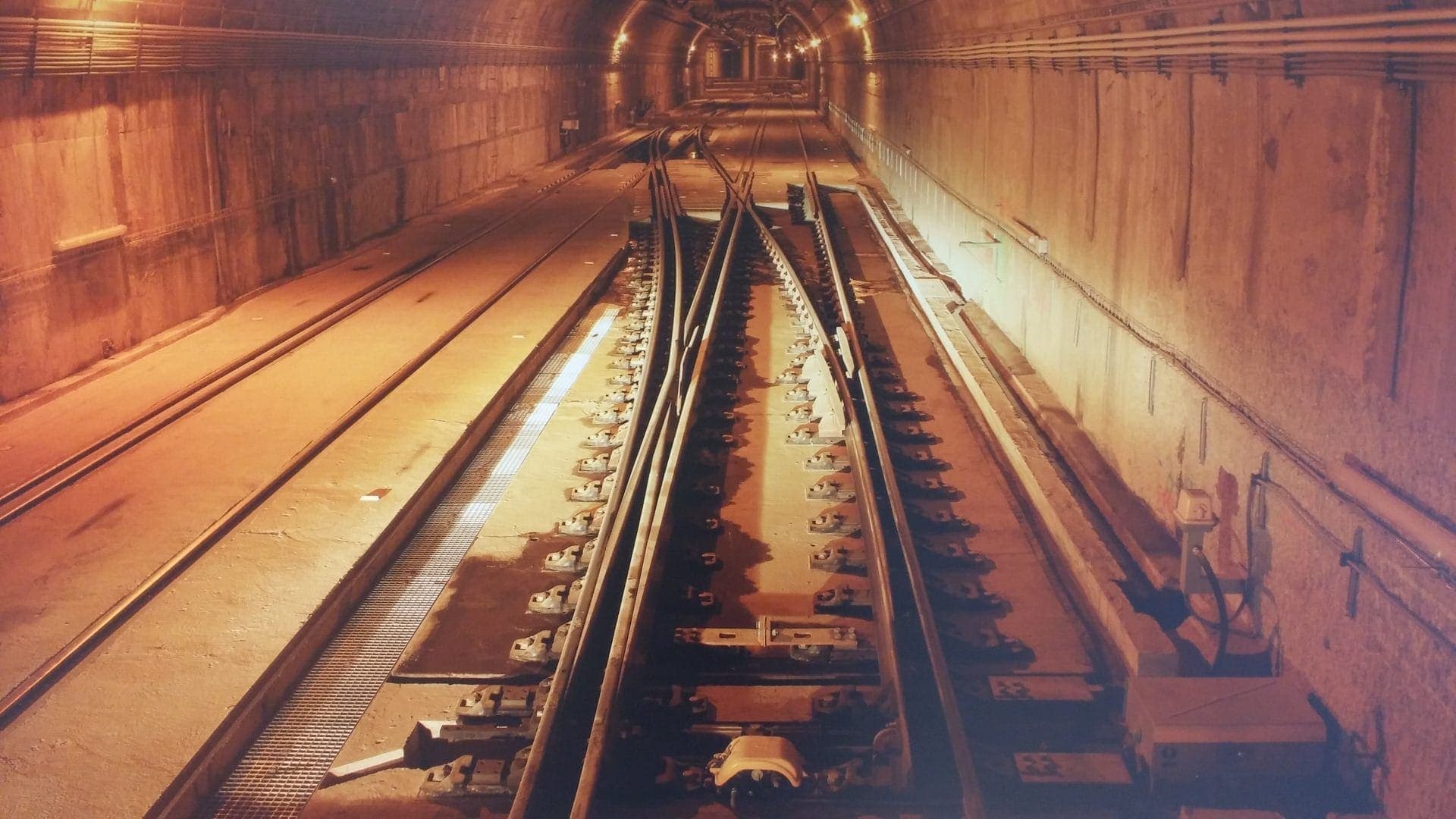

S-CODE: Switch and Crossing Optimal Design and Evaluation

Madrid, Spain

-

9

Participants

-

36

Months

News

The S-CODE R&D project funded by the Europ…

Ver más

The Railway Research, Development, and Inn…

Ver más

The overall aim of the S-CODE project is to investigate, develop, validate and initially integrate radically new concepts for switches and crossings that have the potential to lead to increases in capacity, reliability and safety while reducing investment and operating costs.

Main goal of the Project

The project is included in the European Framework Horizon 2020 and correspond to the Call: H2020 – S2R-OC-IP3-01-2016, specific for Shift2Rail. Shift2Rail is the first European rail initiative to seek focused research and innovation (R&I) and market-driven solutions by accelerating the integration of new and advanced technologies into innovative rail product solutions. Shift2Rail promotes the competitiveness of the European rail industry and will meet changing EU transport needs. R&I carried out under this Horizon 2020 initiative will develop the necessary technology to complete the Single European Railway Area (SERA).

The overall aim of the S-CODE project is to investigate, develop, validate and initially integrate radically new concepts for switches and crossings that have the potential to lead to increases in capacity, reliability and safety while reducing investment and operating costs.

Project Description

The S-CODE project will identify radically different technology concepts that can be integrated together to achieve significantly improved performance for S&C based around new operating concepts (e.g. super-fast switching, self-healing switch).

The project will build on existing European and national research projects (in particular, the lighthouse project In2Rail, Capacity4Rail and Innotrack) to bring together technologies and concepts that will significantly reduce the constraints associated with existing switch technologies and develop a radically different solution.

The project will be divided into three phases:

- Phase 1: Requirements and initial design – focusing on understanding constraints and critical requirements, and developing a radically different architecture and operation that makes use of technologies from other domains.

- Phase 2: Technical development – undertaking detailed modelling and simulation to identify an optimal configuration to maximise performance.

- Phase 3: Validation and evaluation – testing (to TRL4) the design concepts and formally evaluating their performance in order that an integrated design can be presented for further development .

Within the S-CODE project, the carefully selected consortium members will build on existing European and national research projects (in particular, the lighthouse project In2Rail, Capacity4Rail and Innotrack) to bring together technologies and concepts that will significantly reduce the constraints associated with existing switch technologies and develop a radically different solution. As shown in Figure 1, the S-CODE project will run alongside sister projects: (i) the ongoing IN2RAIL lighthouse project, and (ii) the Shift2Rail joint undertaking S2R-CFM-IP3-01-2016 – Research into enhance track and switch and crossing system. It is anticipated that outputs from these projects will feed into the S-CODE project, in order to develop a TRL4 solution that can be later developed into Technology Demonstrator TD3.2 – Next Generation S&C.

Participants

- THE UNIVERSITY OF BIRMINGHAM (United Kingdom)

- Výhybkárna a strojírna, a.s. (Czech Republic)

- FERROVIAL CONSTRUCTION SA (Spain)

- Rhomberg Sersa Rail Holding GmbH (Austria)

- RAIL SAFETY AND STANDARDS BOARD LIMITED (United Kingdom)

- COMSA SAU (Spain)

- LOUGHBOROUGH UNIVERSITY (United Kingdom)

- VYSOKE UCENI TECHNICKE V BRNE (Czech Republic)

- UNIVERZITA PARDUBICE (Czech Republic)

Ferrovial Agroman participation

Ferrovial Agroman will support the academic organisms of the project providing its experience in the following fields; S&C installation, S&C maintenance, S&C logistics, BIM, intelligent infrastructure, high speed railway design and construction and innovative construction.

Resultad Expected Outcomes, Benefits and Impact

The technologies and potential results involved in the project are listed as follows:

- Modular switch and crossing architecture that allows subsystems to be easily changed or upgraded such that the gains in S&C system performance available from the adoption of new concepts can be realized progressively without the need for complete system renewal, thus allowing benefits to be attained more rapidly.

- Resilience-based design methodologies, maintenance free and degradation free systems and self-adjusting technologies that will allow complete self-inspection and self-correcting and healing functionality through the development of an S&C immune system, contributing towards a 50% improvement in the reliability and availability of switches.

- New concepts that utilize new materials and construction techniques, together with an optimised wheel-rail interface to realize a new movement principle which has the potential to contribute to a reduction in the life cycle cost of switches by up to 30%.

- Integrated system, including a fail-safe locking mechanism design is arrived at that mitigates all risks associated with technical failure, human error and influencing external factors, that may result in incidents occurring, thus ensuring that the number and magnitude of incidents is reduced and the safety of passengers and the work force is retained at the highest level.

- Significantly increase the allowable running speed of trains while also dramatically decreasing the switching time in order to contribute to a capacity improvement of up to 100%.

Funding

This project has been granted (100% of the budget) by the Horizon 2020 and the Shift2Rail initiative.

-

50 %

improvement in the reliability and availability of switches

Related projects

See more projects

DINATRANS

TRAILS: Innovative Infrastructure

Crossrail

BIM Technologies

With the collaboration of

Sentinel, a Smart System for Managing and Maintaining Railway Lines

Madrid, Spain

-

€1.44M

Budget

-

€646000

ERDF Funds

The Sentinel project aims to develop a new prototype of a smart system for managing and maintaining railway infrastructure by using structured big data to get a fast, full picture of the state and evolution of the railway line.

The result is a precommercial product in the prototype testing phase for useful application in the medium term.

The consortium for this collaborative project includes our subsidiary brand Ferrovial Construction (leader), Adif, Alstom, and Insitu. With a budget of €1.44 million, it was jointly financed with €646,000 from the EDRF (European Regional Development Fund) through CDTI´s Innterconecta program.

The project, which began in July 2016, aimed to integrate a data-capturing device into maintenance vehicles for railway lines and feed a database with a corresponding system of geographical information. That way, it can update an automatic or semi-automatic inventory of railway assets, at the same time as it reviews and evaluates parts of the railway, thereby optimizing maintenance operations.

This automated inventory of assets gives a fast, dynamic, combined panorama of all the pieces of infrastructure and parts of the network, such as lanes, tap bolts, railroad ties, markers, signals, and more.

The system’s characteristics are continuity and precision, such that continually updating the inventory lets changes in the infrastructure parts be analyzed and tracked over time in order to predict changes, failures, or emergency situations, as well as allowing the monitoring of digital maintenance and inspection by maintenance personnel.

The assets monitored by the inventory have been grouped by subsystems, and the assets management software is capable of integrating them into Adif’s inventory database. Technology related to Industry 4.0 was used to develop it, including big data, machine learning, artificial intelligence and vision, models and simulations, European GNSS, and satellites.

The prototype’s validation tests, which were done in April 2018 on the high-speed Amussafes-Javea line and then in November of the same year on the high-speed Madrid-Chamartín and Torrejón de Velasco line, which is currently under construction, consisted in integrating Lidar systems (which obtain 3D maps and images of the railway though dynamic scans by using technology called mobile mapping systems), GPS, cameras, high-precision recorders, lighting, and more. All this allowed digitalizing this new infrastructure at a traveling speed of 80 km/h on a maintenance vehicle equipped for the tests.

The system includes a software tool that lets the infrastructure parts such as lateral signals, markers, catenary posts, lane fasteners, detours, expansion apparatuses, etc. be inventoried and identified automatically.

Sentinel will allow ¡the assets inventory of the entire Adif infrastructure to be updated automatically in the short and medium term, giving access to real infrastructure data for an asset management system that will allow assets to be analyzed, predicted, and acted on efficiently.

Related projects

See more projects

Strengthening Train Tunnel Embankments

Central Train Station in Wroclaw

Pomeranian Metropolitan Railway

Crossrail

With the collaboration of

SEEDS: Self learning Energy Efficient Buildings and Open Spaces

Madrid, Spain

-

36

Months/Duration

-

€4.4M

Budget

-

8

Partners in Consortium

The SEEDS project consists in the development of an innovative system for optimizing building performance, both single buildings and groups of buildings, in terms of energy, comfort and lifecycle value.

The SEEDS (Self-learning Energy Efficient buildings and Open Spaces) project has Ferrovial Construction’s R&D department as a project partner. It is coordinated by CEMOSA and has been funded through the European Commission’s Seventh Framework Programme for Research.

The project consists of the development of an innovative system for optimizing building performance, both single buildings and groups of buildings, in terms of energy, comfort and lifecycle value, based on building technologies, and technologies for predictive control, self-learning and artificial intelligence.

Using new optimization algorithms, the SEEDS system helps to minimize energy consumption in buildings, while maintaining comfort and air quality within them. The project has developed a network of wireless sensors which are easy to install and compatible with automatic maintenance systems, thus allowing them to be retrofitted during renovation of existing buildings.

Buildings account for over 35% of the European Union’s energy consumption, and the project therefore has the potential to contribute significantly to Europe’s energy consumption and CO2 reduction targets for 2020.

Consortium: CEMOSA (coordinator, Spain), Fraunhofer (Germany), Ferrovial Construction (Spain), Stavanger University (Norway), Salford University (UK), Cidaut (Spain), Softcrits (Spain), NSC (Germany) and FASA (Germany).

Related projects

View all

Sustainable Building Methods

Environmental Protection in a Reserve

TRAILS: Innovative Infrastructure

This project has received funding from the European Union’s Seventh Framework Programme for research, technological development and demonstration under grant agreement No. 285150.